Fountain Pen Brief History

Fountain Pen Brief History

June 25, 2017, extracts from International Stationery Association,

Posted by Kenetic Team, Fountain Pens

Background

Humans have used various instruments to convey thoughts and feelings. Man's first writing instrument was his finger, using it to form symbols in the dirt. Later, pieces of metal or bone were used. Ancient Greeks used a stylus to mark on wax-coated writing tablets, while early Egyptians used hollow reeds as writing tools and papyrus as their writing surface.

During the Middle Ages, quill pens, made from bird feathers whose ends had been split and sharpened, became the writing tool of choice until the development of the steel dipping pen in the early 1800s. Steel pens, which used steel tips called nibs, did not require the frequent sharpening that quill pens did. However, they still needed to be dipped in an inkbottle because they did not contain their own ink.

Even as the steel pen was gaining in popularity, attempts to design a more practical writing instrument were being made. These efforts eventually resulted in one of the most popular writing tools still used, the fountain pen. Lewis Edson Waterman, a New York Insurance Agent, produced the first practical fountain pen in 1884. While both the quill and steel pens had to be dipped in ink, the fountain pen was the first to hold its own ink within a self-contained reservoir. Because of its practicality and durability, the fountain pen became the most popular writing instrument and remained so until the development of the ballpoint pen in 1938. The fountain pen remains popular for its elegance and prestige, both as a writing instrument and a valuable collector's item.

History

Attempts to develop a self-feeding pen that did not require sharpening were made as far back as the beginning of the tenth century. Numerous ideas were developed, but it was not until 1884 that success was finally achieved. Waterman's pen worked as flawlessly as a dipping pen but without the need for an external inkbottle. Waterman started producing these pens at a rate of 36 per week and selling them at his New York City cigar kiosk. However, the demand quickly soared, prompting Waterman to open a six-story production facility on Broadway, which he expanded even more in later years. The fountain pen dominated the writing instrument market for the next 60 years.

Capitalizing on Waterman's success, other companies joined the writing instrument manufacturing business. In 2001, the Writing Instrument Manufacturers Association, an organization comprised of companies that produce fountain pens and other writing tools, had approximately 25 members. The larger companies now use an automated process to produce fountain pens, while some smaller companies and individuals still produce them by hand, just as Waterman did back in 1884.

Although fountain pens are available in a variety of styles offering unique features, each is comprised of the same basic components: the nib, or point; the barrel, which holds the ink reservoir, and the cap, which fits over the nib of the pen to protect it from damage. Ink flows from the reservoir to the nib at a balanced rate of flow by means of a force called capillary attraction. This is the same force that causes a blotter to absorb ink or kerosene to flow up the wick of a flame.

The first nibs were made of gold alloys, often dipped in a hard metal called iridium for strength and resistance to corrosion. However, when gold alloy nibs became too expensive to mass-produce, steel was adopted as the material of choice. Solid gold, ranging from 18-22 karat, is still used for the nibs on some pens. Each nib has a slit at its tip that controls the flow of ink.

The first barrels were made of black hard rubber, chosen because it is ink-resistant and easily machinable. Postwar pens are more commonly made from durable plastic. However, barrels can be made from gold, silver, brass, wood, bone, or even crushed velvet.

The first fountain pens were filled with medicine droppers, which were later replaced with rubber sacs. First used in 1890, these sacs had a short life because the rubber material they were made from was not able to withstand the chemical action of the ink. Rubber compounds were later improved, and a long-lasting rubber sac was introduced in the late 1920s. This sac was later replaced by an even better semi-transparent, plasticized vinal resin sac containing no rubber. Various forms of sac depression mechanisms have been used throughout the years. The first sacless pen was introduced by the Parker Pen Company in 1932.

Raw Materials

Fountain pen barrels can be made from a wide variety of materials. Finer, more expensive pens are made from materials such as brass, silver, or gold. Modern pen manufacturers generally use less expensive materials for pen barrels, including: acrylic resin, also known as Lucite or Perspex, which is used for Parker 51 models; cellulose acetate; and various other injection-moldable polymers. Handmade pens can be created from wood or almost any other material that is solid, stable, and can be worked with standard woodworking tools. Examples include plywood, crushed velvet, bone, leather, and even antlers. Stainless steel is generally used to make the nibs, although gold or sterling silver may also be used. The clips and other fittings are usually made from a gold alloy that has been electroplated, or they may be gold or gold filled on finer pens.

Design

Fountain pens are available in a variety of designs and styles. Some are mass produced while others are custom-designed. With custom-designed pens, the creator must decide ahead of time what special features the pen will have and choose the appropriate tools and process to use based on those features. Some possible variations on design include laminating strips to produce intriguing patterns and color combinations, changing the style of the clip to give the pen a different look and feel, carving or burning a unique design into the surface of the pen, or inlaying gemstones or other materials into the pen surface. All of these design variations require some extra preparation and materials, but help make the pen unique, and sometimes, more valuable.

Refill mechanisms

A variety of mechanisms can be used to fill fountain pens. These include levers, buttons, pistons, and squeeze bulbs. Lever-fillers have a tiny lever built into the side of the pen. Lifting the lever causes the ink sac to compress. Then, after the nib is dipped in ink, closing the lever causes the sac to reinflate. Button-fillers have a button on the end of the pen. The button works similarly to the lever; pressing the button causes the sac to deflate, and releasing the button causes the sac to reinflate after the pen has been dipped in ink. Piston-fillers use a screw mechanism to move a piston inside the barrel, taking in and expelling ink, while squeeze bulb fillers are filled by repeatedly squeezing the bulb. Each one of these mechanisms are installed on the pen during final assembly.

The Manufacturing

Process

The larger pen manufacturers use automated processes to produce fountain pens. However, some smaller companies and individuals continue to create pens manually. The materials and processes used by different companies and individuals vary. Here is a common process used to create handmade pens from wood. This same process, or similar processes, can be used to create pens from other types of materials as well.

Manufacturing individual fountain pens from wood.

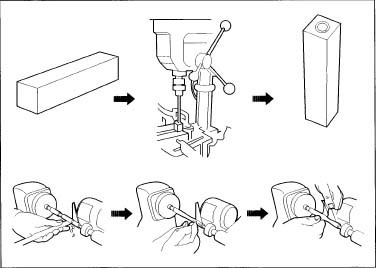

Preparing the blank

1. The first step in creating the pen is to prepare a blank, a rectangular piece of wood that will be filed and shaped into the two halves of the pen barrel. Virtually any type of wood can be used. However, it must be dry when the process begins. Colorful woods with interesting patterns are preferable because they make for a more attractive finished product. To prepare the blank, the wood is first cut into a rectangle approximately 0.75 in 2 × 5 in long (1.9 cm 2 × 12.7 cm).

2. Then, the blank is marked with a line (called a match mark) extending about 1 in (2.5 cm) beyond where a cut will be made separating the blank into two halves, an upper and a lower. The blanks are then crosscut into lengths that are slightly longer than the brass tube that will eventually be inserted into them. One way for the crosscut to be made is with a bandsaw equipped with a miter gage and an auxiliary slip fence, which is an adjustable fence especially made for cutting different lengths of pen blanks.

3. The blanks are then held in place using a jaw clamp or some other similar method, and a hole is drilled down the center of each half of the blank in preparation for the insertion of the brass tube. Each blank section is held in place with the match marks facing up.

Inserting the brass tube

4. Once the holes are drilled, polyurethane glue is applied to both the outside of the brass tube and the inside of each drilled hole. Then, the tube is inserted into the blank using a rotating motion to distribute the glue evenly. After approximately 10 minutes, the glue is usually dry and the tube stays securely in place.

5. With the pen secured, the tube is trimmed to fit precisely in the blank using an adapter sleeve and a barrel trimmer until a brass curl is produced.

Mounting and turning the blank

6. Once the tube is inserted, the upper and lower blanks are ready for mounting on a mandrel in preparation for turning. A split mandrel system, consisting of two short steel mandrels, is generally used. Each blank is mounted separately on the split mandrel along with the appropriate bushings.

7. As each blank spins, the wood that does not belong on the pen is carefully cut away using a gouge or similar tool. Finishing cuts are made using a skew chisel.

8. A notch is carved around the upper blank, completely through to the tube, using a thin parting tool. This notch is where a metal trim ring will later be inserted.

Sanding and finishing

9. Now the blanks have turned into pen barrels, ready for sanding and finishing. Sandpaper, starting with 120-grit and progressing to 180-grit, 220-grit, and finally 320- or 400-grit, is used to ensure a smooth finish. If Dymondwood is used, a grit as fine as 600 may be necessary for a high gloss finish.

10. The pen barrels are coated with a wax Vo r plastic polish, applied with a soft cloth while the barrels are still spinning.

Preparing for assembly

11. Prior to assembly, the sharp corners on each end of the finished barrels are sanded slightly.

12. If a clip is to be used, a notch is cut in the upper barrel in preparation for its insertion. To avoid chipping the wood, a grinding wheel or a file is used to cut this notch.

Clips, fittings, and bands

13. The clips and metal fittings used on fountain pens are stamped, just as when the fountain pen was first produced. Bands and overlays are rolled from sheet metal and hard soldered.

Final assembly

14. Now the ring, clip, and other metal trimmings are attached to the finished barrels to make a completed pen. A drill press and press jig may be used to press the pen parts together. The drill press is used as a vice, while the jig (a long, flat piece of wood with metal posts sticking up) is used to keep the parts in line during assembly. First, a nib coupler is pressed into the large end of the lower barrel. Then the lower barrel is flipped over, and an end cap is pressed into the smaller end. The nib is then inserted into the nib coupler.

15. Next, the trim ring and clip assembly are inserted into the previously created notches in the upper barrel. Then a closing cap is screwed in place using a cap adjuster tool or Phillips screwdriver to complete the assembly of the upper barrel.

16. Finally, the two barrels are screwed together and the fit is tested and adjusted with the cap adjuster or screwdriver if necessary.

Automated process

The process used to make fountain pens at larger companies is generally more automated. These companies use specially tooled machines to mold the pen barrels, usually from molten plastic. Machines also do the stamping and crimping of the metal parts, assemble the final product, and even take care of the polishing and cleaning.

Quality Control

Although there are no official guidelines governing the manufacture of fountain pens, most companies have a series of set inspections to ensure quality. They test for defects in the surface of the pen, the quality of the ink flow, the fit of the cap, and so on. Some pens even come with certifications to attest to the quality of the finished product. For example, the Parker 75, one of the Parker Pen Company's more famous models, undergoes 792 inspections and comes with a certificate of quality signed by the final inspector.

The Future

Although ballpoint pens have replaced the fountain pen as the universal writing tool, fountain pens continue to be popular with collectors as well as those who desire a more elegant and sophisticated writing tool. According to sources from Parker, the fastest growing markets for fountain pens in 2001 are in the Far and Middle East and in Europe.

One trend in the fountain pen market is the growing number of individuals who have begun manufacturing and selling pens on their own. This is made possible by the availability of pen kits containing all the materials and instructions needed, and by the popularity of the Internet as a means of selling handcrafted pens to a larger market.

- Pre:Fountain Pen Nibs Specificatio 2017/6/25

- Next:None